Adapting to life under the coronavirus pandemic was no easy feat. Yet despite the challenges, pharmaceutical company Farmak did not stop production. On the contrary, the company kept all its contractual obligations and even increased output of some drugs.

The company immediately reacted to the crisis to ensure the safety of staff and uninterrupted production, promptly moving to product disinfectants both for internal and external use.

Also company organised a shift to remote work, a halt to business trips, rigorous sanitation and hygiene procedures (with disinfectants installed at work premises) and safety protocols for anyone exhibiting symptoms.

The company even put in place a system of routes and centralized transport of the company’s employees from their places of residence to work – ensuring the continued smooth operation of the enterprise, while minimizing risk to staff.

“Farmak” also made sure to help others via the All-Ukrainian Charitable Organization Zhebrivsky Family Charitable Foundation (successor to the Farmak Charitable Foundation), which allocated UAH 10 million to counter the spread of the coronavirus.

The fund purchased ventilators for hospitals in Kyiv, Shostka and Ruzhyn. A total 7 hospitals, including the Chasov Yar military hospital in Donetsk region, received protective gear, medical masks and gloves, respirators of protection class FFP2 and FFP3, goggles, disinfectants and medicines.

The foundation will also provide Ukrainian physicians with 4,000 protective suits sewn from special materials that meet European quality standards.

A market leader

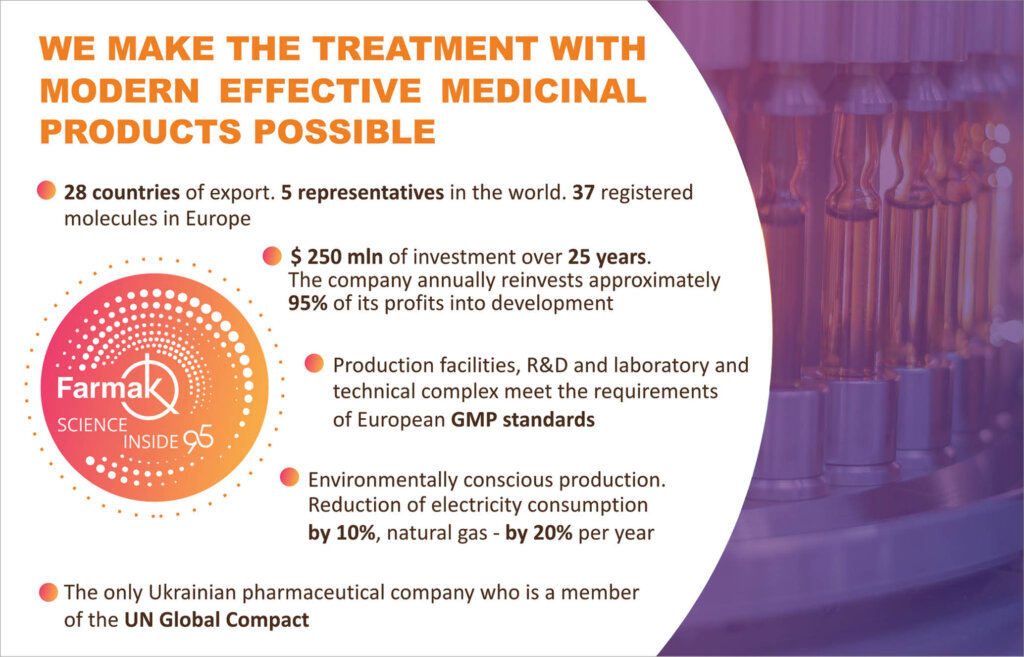

“Farmak” is Ukraine’s pharma leader with a 5.9% market share and topped the industry’s innovative leader ranking in 2019. The introduction of modern technologies, advanced equipment and innovative solutions to production and management aligns with the company’s core philosophy and its main competitive advantage.

The company produces drugs belonging to all 14 therapeutic groups, with one of the biggest portfolios in anti-cold, endocrinological, gastroenterological, cardiological, neurological. Each year it brings some 20 new drugs to the market and has around 100 drugs under development.

The company annually reinvests approximately 95% of its profits into development. Over the past five years, “Farmak” invested UAH 3.4 billion into production, scientific and technical equipment, and research activities. This helped expand production by 35% over that same period.

Ukraine’s strategic healthcare challenge

One of the key problems of Ukrainian pharmaceutical industry is the dependence on foreign imports which account for 50-70% of most drug categories. Reducing these imports is a strategic issue for the country and for the country’s security.

But ensuring that key drugs are produced domestically, and hence lowering the risk of shortfalls, will not happen with the government’s support. The state should have a list of medicines that will be fully manufactured at domestic facilities using domestic raw materials

Support is needed to develop domestic alternatives, notably generic drugs that can be provided to patients at lower costs.

Export opportunity

Export presents the biggest opportunity. In recent years, Ukrainian pharmaceutical manufacturers have begun to export to such countries as Brazil, Iraq, Cuba, Colombia, the Philippines, and Australia. They have also significantly increased supplies to Poland, Vietnam, Mongolia, and India.

“Farmak” has operated in EU markets for over 20 years, including Poland, Bulgaria, Latvia, Lithuania, Hungary, Great Britain and Germany. Today we work with the EU, ASEAN and MENA regions, with plans to expand focused on Asia, Latin and North America, and the EU.

Our strategic goal is to increase exports by up to 40% of sales from 24% today. This will help boost the sector overall, which is increasingly becoming visible in the world and can be a great benefit to the Ukrainian economy.

* By monetary value of drug sales, according to Proxima Research

** According to the magazine TOP 100